Investment / smart material products

Investment / smart material products

Editorial team

IRPC moves ahead to invest in the largest production capacity of smart material products.

IRPC is spending over 589 million baht to advance three projects of smart material products including 190,000 tons per annum of spunbondPP, the largest production capacity in the country, in response to the world’s healthcare trend.

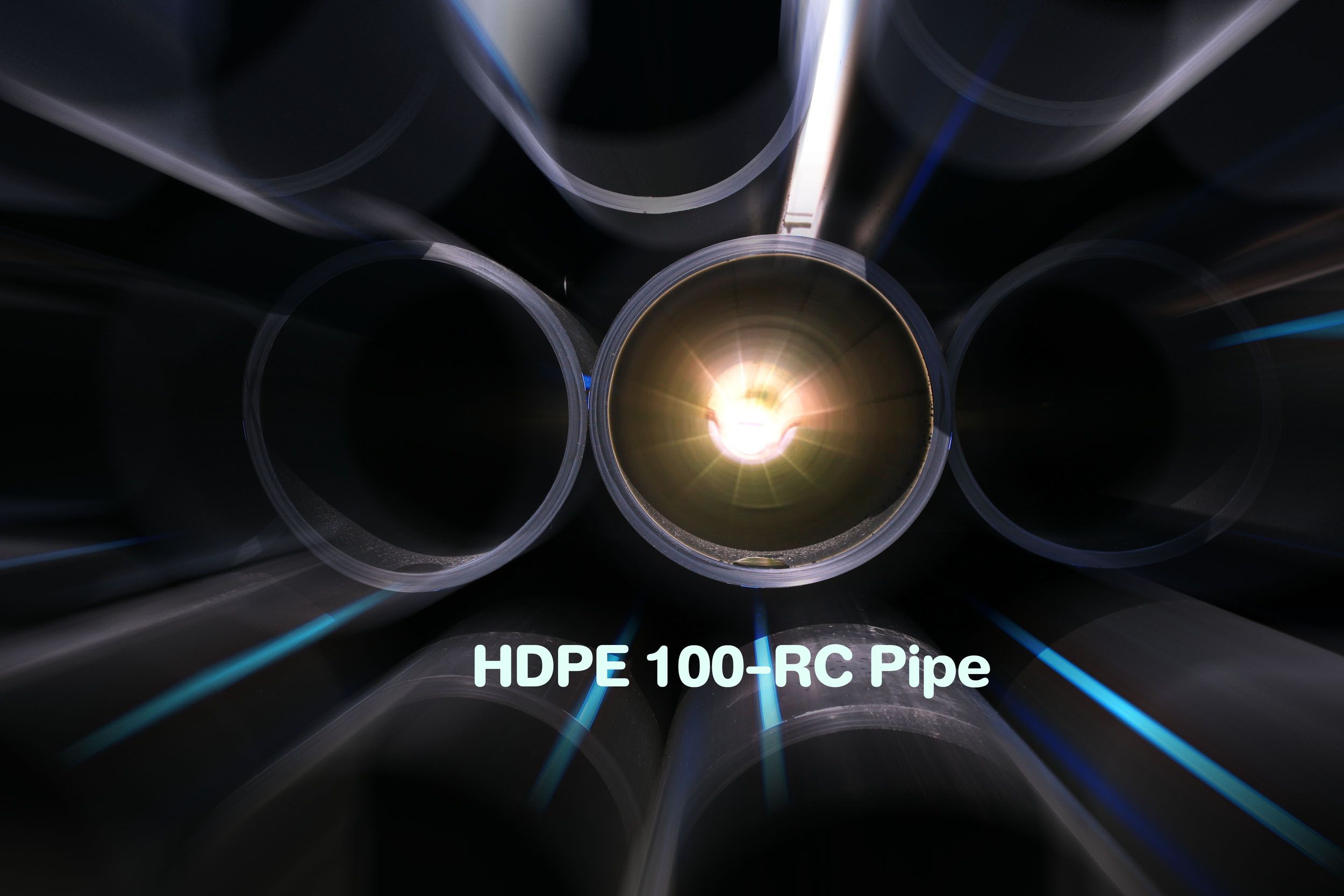

Being the first in the region, the investment also covers 80,000 tons per annum of non-phthalate PPR or PP random copolymer pipe grade for the production of heavy-duty and non-toxic cold and hot water pipes, as well as 40,000 tons per annum of HDPE 100-RC for the production of large industrial pipes which are highly durable and long-lasting up to 100 years. The products will be ready for launch in the market by 2024.

Mr. Kris Imsang, president and chief executive officer of IRPC Public Company Limited (IRPC) said that IRPC is spending capital expenditures of over 589 million to expand its production capacity of specialty products for 3 projects including the spunbond PP production capacity expansion project from 48,000 to 190,000 tons per annum worth 162 million baht, the pipe-graded PPR production project of 80,000 tons per annum worth 200 million baht, and the HDEP 100-RC production project for large industrial pipes worth 227 million baht. The three projects are expected to be completed by 2024 to serve both local and overseas market.

The production capacity expansion of spunbond PP is regarded as the largest capacity in the country. Moreover, non-phthalate production technology is utilized to ensure the highest safety for consumers.

The production process also enables the reduction of carbon emission up to 2,665 tons per annum by utilizing alternative energy from the Floating Solar Farm. The execution is scheduled for completion in the the second quarter of 2024.

Some parts of the products will be allocated for non-woven fabric factory, Innopolymed Co., Ltd. for further development of medical products and quality healthcare products e.g. medical masks, N95 masks, gown, PPE gown, baby and adult diapers as well as filters.

In terms of PPR production project for the production of household and industrial hot and cold water pipes, they are resistant to scratches and pressure as well as are more durable to chemicals than ordinary water pipes. They are also safer due to non-phthalate production technology. Being the first in Southeast Asia region, the project is expected to be completed in the 3 rd quarter of 2024.

As for HDPE 100-RC production project for the production of large industrial pipes, they are highly resistant to impacts and scratches. Usage is also long-lasting for over 100 years. These qualifications will help reduce construction cost from utilizing soil drilling machine and laying underground pipes instead of excavating soil surface. As a result, natural resources and environment will be preserved. At the same time, construction period can be reduced. The project is expected to be completed in the 1st quarter of 2024 as well.

Mr. Imsang said that IRPC’s investment in smart material products is in congruence with the global megatrends of health and wellness, which will play an important role in people’s ways of living in the new age.

The investment will also support the national strategy, particularly in medical industry, which is one of the new S-curves according to Thailand 4.0 policy, to support the expansion of urban society as well as investment projects in infrastructures both locally and abroad. This is also in congruence with IRPC’s vision to further develop innovation that create values for the society and the environment under the vision “To Shape Material and Energy Solutions in Harmony with Life”.

03 November 2022

Viewed 259 time

EN

EN